in our production means:

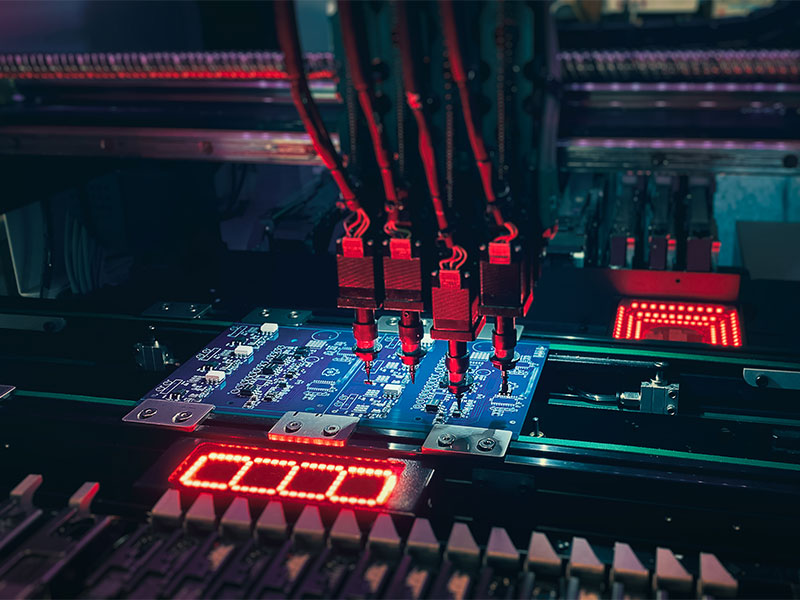

- Excellence in metal | Electronics | Plastic

- Uniquely high production width and depth

- As a one-stop shop, we offer pragmatic and economical solutions

- Quality and precision reflect our claim to excellence

- Technology leader through consistent innovation

- Utmost precision in production and assembly

- The degree of automation is always adapted to the required batch size

- Consistent digitalization of the manufacturing processes

- Use of artificial intelligence

- Scalable processes from small series to large series

...LEADING OUR CUSTOMERS TO SUCCESS

We offer you holistic individual solutions made of metal | electronics | plastic or mechatronic systems.

You benefit from us as a system supplier, or you can also use only individual technologies from our portfolio to manufacture your product.

The special production expertise of the BURGER GROUP

We produce mechatronic systems, drive solutions, and individual parts, including motor, electronics, sensors, housing, and gearbox. The bundled expertise in the BURGER GROUP with mechanics, electronics, software as well as tool and mold making are our success factor.

The depth of production with the diverse and complementary production technologies at the BURGER GROUP is probably unique. Our customers and their requirements are as diverse as our technologies. In terms of commercial, technical, and logistical aspects, we always find a suitable solution at one of our locations in Europe and North America, from prototypes with batch size 1 to large-scale production with several million units per year.